The ELC Series is our most compact unit. Its small footprint gives the client a great value for their money with the same reliability and capacity that all Electrichlor systems are known for. The system is designed to allow for doubling of output capacity without having to reconfigure the skid.

The ELA Series offers a small footprint generator featuring the same robust cell technology that is utilized in all of Electrichlor’s systems. The ELA Series offers different control panel options by allowing for the integration of the control panel into a new or on-site Programmable Logic Controller (PLC) system without requiring any special reconfiguration, thereby more efficiently adapting to the needs of your project.

Electrichlor’s ELX Series represents our most robust lineup of hypochlorite generators. Its modular design allows the user to upgrade the capacity of the generator with ease. With all the necessary parts on site, increasing the capacity of the system can be done in less than 45 minutes and with the minimal training of onsite personnel. The different configurations that this Series offers provides great project adaptability.

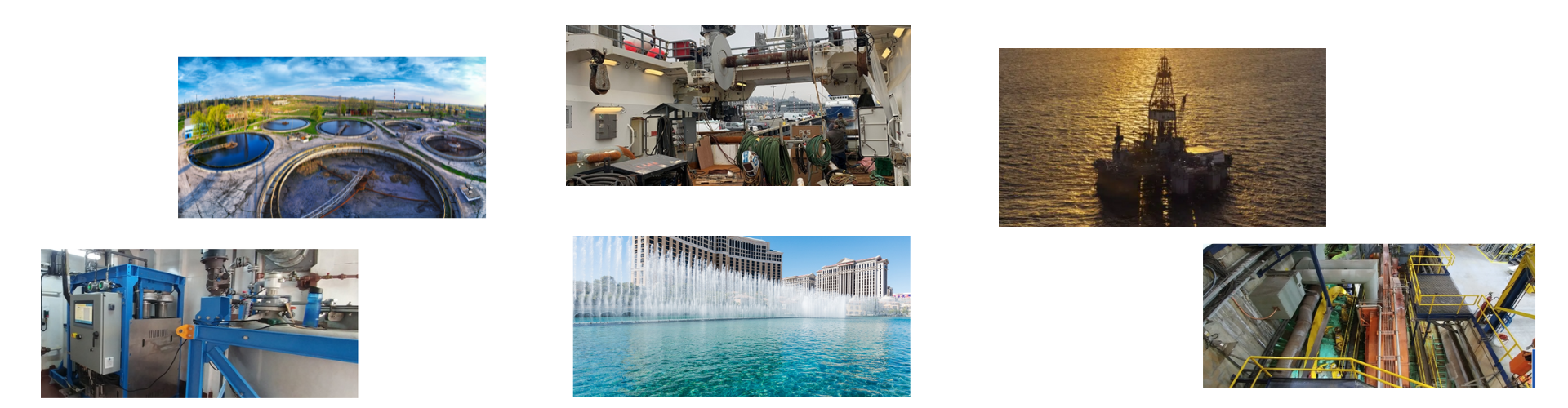

APPLICATIONS

Water & Wastewater Treatment - Power Stations - Fishing Vessels

Ballast Water - Offshore - Decorative Water Bodies

WATER AND WASTEWATER TREATMENT

According to the CDC, chlorine is one of the major disinfectants utilized in Public Owned Treatment Works (POTW) facilities. As such, this disinfectant is commonly found in the water that we all consume every day. Furthermore, the EPA has provided guidance to ensure safe chlorine levels are maintained within all POTWs.

In recent years, due to the pandemic of 2020, there have been notable supply chain issues that have resulted in a dramatic increase in the price of delivering bulk bleach. As a result, many POTWs and industrial facilities have begun to look for more cost-efficient alternatives to purchasing bulk bleach. On-site Hypochlorite Generation (OSHG) can provide a more economical solution to plant operators by enabling generation of a safe disinfectant that kills or inactivates harmful microorganisms on site. The savings is directly attributable to reduced transportation costs and the ability to maximize cost efficiencies of water usage and elimination of bulk chemical supplier markups and profits.

POWER STATIONS

On-site hypochlorite generation (OSHG) has been used effectively for many years in the power industry to control marine growth in the pipework of cooling water systems at power stations. Generally, seawater-cooling systems for power stations utilize OSHG to control algae and mussel growth that can block intake systems and severely impede the flow of seawater to condensers and heat exchangers. These systems divert a small flow of seawater to an OSHG to produce sodium hypochlorite (NaOCl), generally at levels between 1000 and 2000 ppm, which is well below the threshold level for hazardous material, (10,000 ppm), as mandated by the EPA.

By keeping a constant dosage at 1 ppm of chlorine in the cooling water system, marine growth is impeded from clogging cooling water systems. The application is not limited to sea water. By using salty water in place of seawater, fresh water supplies can be effectively chlorinated using the same technology without the dangers associated with gaseous chlorine.

Generally, hypochlorite generators are installed adjacent to the seawater cooling water pumps and receive their seawater feed from the pressure side of the cooling water pumps. Hypochlorite at 2000 ppm is piped to the pump suction to ensure the entire cooling water system is treated.

FISHING VESSELS

Chlorine has proven to be effective as a sanitizing agent within fishing vessels that process seafood onboard. Specifically, On-site Hypochlorite Generation (OSHG) systems have been installed in commercial fishing trawlers for chlorinating sea water used onboard the vessels for the purposes of washing off fish scale, slime and blood from eviscerated fish processed onboard while at sea, as well as for washing and sanitizing the vessel processing facilities while at port.

Electrichlor designs and manufactures equipment for the maritime industry with conformance to ABS, IEEE & NEMA. Our OSHG systems are very compact and able to fit in tight onboard quarters with minimal pipework, which makes them ideally suited for both new ship builds and retrofit applications. We have numerous OSHG systems successfully operating in the north Pacific onboard trawlers and other commercial fishing vessels. Our support services and overall understanding of the importance of keeping production equipment running at all times is paramount; we understand that the luxury of having an onboard repairman to make an emergency call is not always an option while at sea. Electrichlor provides an unparalleled superior design that ensures no “down time” while at sea, but also provides onboard support service in the rare instance there is such a need.

BALLAST WATER

Utilizing water within the ship ballast to steady vessels at sea has been a long-standing design feature since the emergence of steel-hulled boats. During a sea journey, seawater is pumped into the ship’s ballast to ensure safe operating conditions. This method decreases hull stress, increases transverse stability, enhances propulsion and maneuverability, and adjusts for weight variations owing to cargo load levels and fuel and water consumption.

While ballast water is necessary for safe and efficient maritime operations, the number of marine species carried in ballast water may cause major ecological, economic, and health difficulties. Bacteria, microorganisms, microscopic invertebrates, eggs, cysts, and larvae of many sea species are among them. The transplanted species may live in the host habitat and develop a reproductive population, becoming invasive, outcompeting native species, and growing to pest proportions. Electrichlor provides On-site Hypochlorite Generation (OSHG) systems that mitigate this invasive species development and control the ballast water to ensure safe compliance for treatment and disposal into maritime environments.

OFFSHORE PLATFORMS

Bio-fouling is a constant issue in any offshore operation. Dealing and handling hazardous biocides can be a constant danger for the operation crew, including requiring Personal Protective Equipment (PPE) that must always be used while handling any dangerous chemicals. For the chlorination of wastewater, firewater, sewage, gray water and potable water services, an On-site Hypochlorite Generation (OSHG) system is placed on the platform and is equipped with several outlet connections to treat the various dosing requirements. On oil-production platforms where the OSHG system is to be placed in a hazardous location, the system is installed in a sealed and purged containment vessel. OSHG avoids the problem of processing and handling bulk chemicals while providing a safer alternative to the bio-fouling needs in remote locations such as an offshore platform.

Electrichlor’s OSHG systems provide a solution to control marine growth for offshore oil refineries and production platforms. Our systems are suitable for indoor locations, or outdoor locations when installed on an appropriate structural foundation and shaded from direct sunlight.

DECORATIVE WATER BODIES

Large decorative bodies of water around the world often encounter unique water quality challenges, one of them being able to effectively manage the levels of harmful bacteria such as e-coli, giardia, and cryptosporidium. Electrichlor’s On-Site Hypochlorite Generation (OSHG) systems have proven to provide a significant cost reduction for decorative waterbodies within waterparks, casino and hotel fountains, and exclusive resort properties when compared to buying bulk chemicals.